800-764-7473

Local 208-324-2142

In the dynamic field of industrial infrastructure, the role of an industrial piping company cannot be overstated. These companies stand at the forefront of delivering robust solutions for fluid transport across various sectors. Whether it’s for manufacturing plants, water treatment facilities or oil and gas pipelines, the choice of piping material significantly impacts the system’s efficiency, durability and safety.

Steel pipes represent the quintessential element in the framework of modern industrial operations, providing unmatched strength, durability and resistance to adverse conditions. When an industrial piping company assesses the needs of a project, steel pipes often emerge as the top recommendation, especially for applications where resilience and longevity are non-negotiable. These pipes, engineered to transport substances under extreme temperatures and pressures, demonstrate their indispensability in oil and gas pipelines, steam systems and high-pressure water systems. Their robustness ensures that industries can rely on a secure and efficient flow of materials, which is essential for maintaining operational integrity and safety standards.

Steel pipes serve as critical components in a myriad of structural applications, including the erection of frames, the assembly of scaffolding, and the development of bridges and edifices. These pipes play a pivotal role in the oil and gas sector, facilitating the efficient transport of fluids and gasses across extensive distances. An industrial piping company might choose steel pipes not just for their physical capabilities but also for their economic benefits, offering a cost-effective solution over the long term due to their low maintenance requirements and durability. The selection of steel pipes is tailored to suit specific project demands, with various grades available to meet different specifications.

Within the oil and gas industry, these pipes are indispensable for executing drilling operations and managing wells, in addition to their vital function in pipeline systems for the conveyance of oil and gas.

Furthermore, steel pipes are integral to the fabrication of industrial machinery and equipment. They form the backbone of conveyor systems, are essential in the crafting of heat exchangers, and are crucial in boiler production. The automotive industry also relies on these pipes for the creation of critical components such as exhaust systems and suspension parts, underscoring their versatility and importance across multiple sectors.

Copper pipes stand out in the industrial sector for their exceptional thermal conductivity and corrosion resistance. These traits make them invaluable in applications where temperature control and material longevity are crucial. An industrial piping company often opts for copper pipes in heating and cooling systems, including HVAC units and refrigerant lines, where efficient thermal transfer is key to system performance. Their reliability is not just a matter of efficiency but also contributes to the sustainability of systems over time, minimizing the need for frequent replacements and repairs.

The antimicrobial properties of copper add another layer of utility, making these pipes a favored choice for water supply systems where cleanliness and safety are paramount. This feature is particularly appealing to an excellent industrial piping company looking to offer solutions that ensure the health and safety of end-users. Copper demonstrates its versatility by serving a wide range of industries, from healthcare facilities that demand sterile environments to residential buildings seeking dependable plumbing solutions. Thus, copper pipes conduct fluids with reliability and efficiency, underpinning the diverse needs of an industrial piping company’s clientele.

PVC pipes are celebrated for their lightweight, cost-effectiveness and versatility, making them a staple in the portfolio of any industrial piping company. These pipes are particularly beneficial for water treatment, sewage systems and agricultural irrigation projects, where their chemical resistance and ease of installation significantly reduce both upfront and long-term costs. Their ability to withstand a variety of chemical interactions without degradation makes PVC pipes a practical choice for a broad spectrum of low-pressure applications, streamlining operations in industries ranging from agriculture to municipal water management.

An industrial piping company values PVC pipes not only for their functional benefits but also for their environmental advantages. Being lightweight reduces transportation emissions and their long lifespan minimizes the need for frequent replacements, contributing to sustainable operational practices. Moreover, the adaptability of PVC pipes to different configurations and settings enhances an industrial piping company’s ability to tailor solutions to specific project requirements, ensuring optimal performance and efficiency. This blend of practicality, cost-effectiveness and environmental consideration positions PVC pipes as a versatile solution in the industrial piping landscape.

Renowned for their exceptional durability, flexibility and resistance to chemicals and environmental stressors, HDPE pipes prove indispensable for challenging industrial applications. An industrial piping company leverages the unique properties of HDPE pipes in projects that demand resilience against harsh chemicals or require adaptability in varied terrains. These pipes are a go-to solution for municipal water systems, industrial wastewater treatment and mining operations, where their ability to maintain integrity under demanding conditions ensures the reliability and safety of fluid transport systems.

HDPE pipes earn favor from industrial piping companies due to their environmental resilience and ease of installation, significantly reducing project timelines and costs. Their corrosion resistance extends the lifespan of infrastructure, while their flexibility reduces the number of fittings needed, further minimizing potential leak points. This combination of durability, flexibility and cost-efficiency makes HDPE pipes a favored choice for an industrial piping company aiming to deliver robust and sustainable solutions to its clients, reinforcing the value of HDPE pipes in the industrial sector’s quest for durability and reliability.

When comparing materials, steel pipes consistently emerge as the top contender for a multitude of industrial applications. Their unparalleled strength, ability to withstand high temperatures and pressures and longevity make them a preferred choice for an industrial piping company. Steel pipes’ adaptability to various coatings and linings enhances their corrosion resistance, making them suitable for even the most challenging conditions.

Steel pipes’ versatility extends beyond their physical properties. They can be manufactured to meet precise specifications, ensuring optimal performance for any application. From small-diameter pipes for intricate systems to large ones for major infrastructure projects, steel pipes offer the flexibility that industries require.

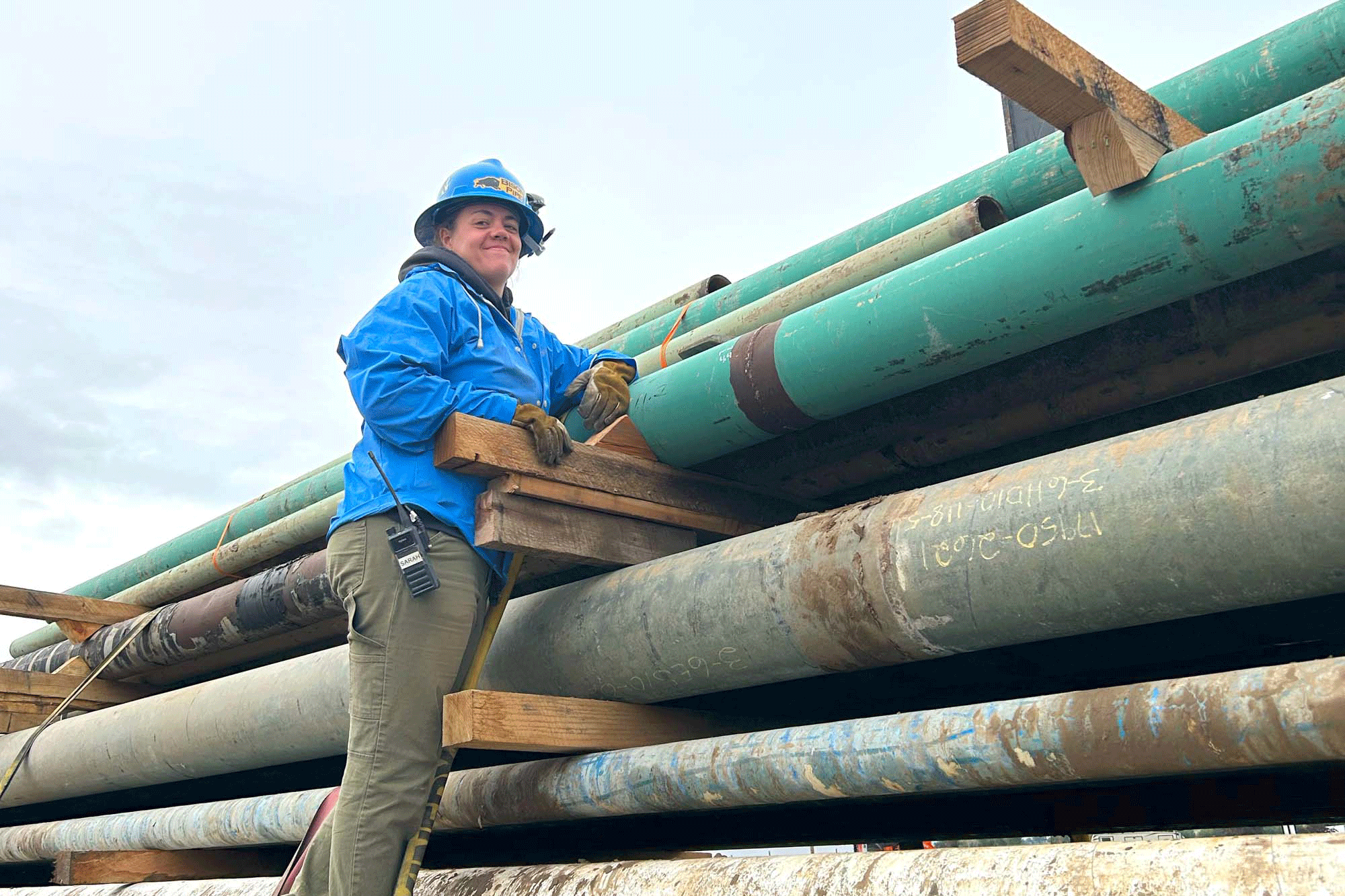

With a legacy of excellence and a commitment to innovation, Bison Pipe is the premier choice for all your industrial piping needs. Our team of experts understands the intricate demands of various sectors, and we are here to ensure that your projects run smoothly, efficiently and cost-effectively. Our dedication to quality, backed by years of industry experience, makes us the industrial piping company of choice. Call us to know more.